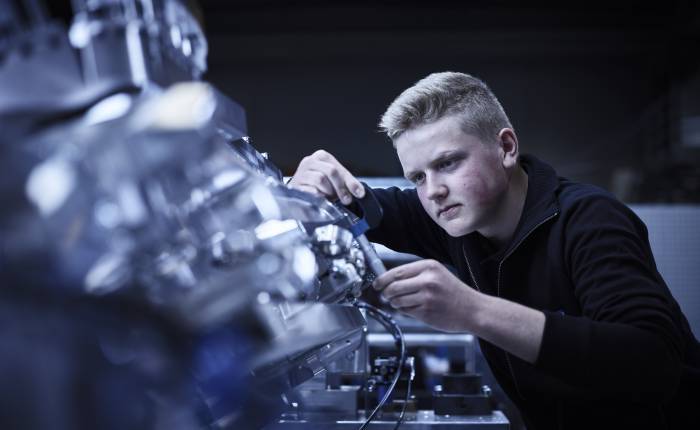

“I find the variety and diversity of my apprenticeship as a mechatronic engineer extremely exciting. But what impresses me most is the trusting and open collaboration with my training supervisors and the solidarity of the entire team.”

FUTUREPROOF SOLUTIONS FOR MANUFACTURING INDUSTRIES

We are 3CON. We develop and manufacture high-end production systems for the leading automotive industry, pharmaceutical and medical industries and their suppliers. We are thinkers, courageous forerunners, dedicated solution finders and precise and reliable implementers: with more than 25 years of experience in the automotive industry while keeping a watchful, forward-looking eye on our customer´s demands and future challenges.

3CON APPLICATIONS

Automotive Industry

Pharmaceutical | medical industry

%

%

Sek.

>

MANY PEOPLE TRAVEL THE WORLD TO DISCOVER NEW FRONTIERS. WE DRIVE TO WORK.

We are continually looking for additional, experienced specialists as well as dedicated young professionals and inquisitive apprentices. Become a member of 3CON and apply today.

3CON Locations

AUSTRIA . HQ

3CON Anlagenbau GmbH

Kleinfeld 16

6341 Ebbs

AUT

Germany

3CON GmbH

Rosenheimer Straße 30b

83080 Oberaudorf

GER

USA

3CON Corporation

47295 Cartier Dr.

Wixom/Michigan, 48393

USA

Mexico

3CON International S.A. de C.V.

Parque Industrial Advance Aeropuerto

Modulo 18, Navajas, Querétaro

C.P. 76246, MEX

China

3CON China Machinery Co., Ltd.

Building A3, No.2 Shiyang Road

Jianzhou New City , Chengdu,

641400, Sichuan, CHN